Reshoring Your Plastic Injection Molded Components: A Strategic Approach

Comments Off on Reshoring Your Plastic Injection Molded Components: A Strategic ApproachThe changing conditions in the global marketplace have manufacturers reconsidering just about everything, particularly their supply chains. Whie this environment can be challenging, the goal remains simple: to continue to maximize profit and efficiency, while minimizing risk. Tariffs in particular have placed urgency on these considerations. But the case for reshoring your plastic injection molded […]

Converting Metal Parts to Plastic Injection Molded Parts

Comments Off on Converting Metal Parts to Plastic Injection Molded PartsToday, manufacturers are constantly looking for effective ways to reduce costs while improving product performance and production efficiency. One way to achieve this is by shifting from traditional metal parts to thermoplastic ones. There are several advantages to doing this besides cost reduction, such as increased design flexibility and reduced part weight. However, not all […]

Plastic Injection Molding Process Variables

Leave a CommentInjection molding can be a complex process, with many factors influencing the quality of the final plastic part. Successful production relies on several critical factors including part design, material selection, tool design, and an optimized manufacturing process. While it’s important to focus on these, another key to part quality and consistency lies in understanding and […]

Surface Finish Standards in Injection Molding: A Comprehensive Guide for Design Engineers

Leave a CommentSurface finish specifications are one of the most frequent topics of discussion when developing new injection molded components. In fact, an earlier blog titled Surface Finish, Texture & Draft Angles In Injection Molded Part Design, has generated much discussion with our clients and prospects, particularly around surface finishes. Today, we’ll dive deeper into the topic, […]

High Volume Injection Molding: An Overview

Leave a CommentHigh Volume Injection Molding: An Overview High volume injection molding is a specialized plastic manufacturing process that produces large quantities of identical parts efficiently and cost-effectively. It is found in many applications that require large quantities of quality parts. Major markets include automotive, industrial, medical, defense, firearm accessories, and consumer goods among other critical applications. […]

Plastic and Rubber Molding 101: Materials, Manufacturing Processes and Applications

Leave a CommentPlastic and rubber molded parts are everywhere, and are produced from an extensive array of materials. While the complete list contains hundreds of varieties, they fall into four basic categories: thermoplastic, thermoset, rubber and silicone. Each group has its unique set of characteristics, advantages, and applications. Due to the differences in their material properties, they […]

Plastic Injection Molding 101: An Overview

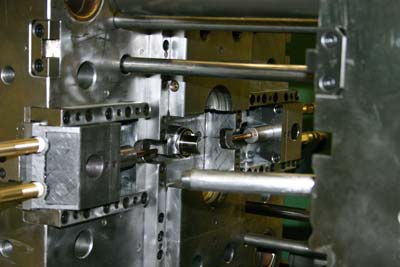

Leave a CommentPlastic injection molding is a complex fabrication process used to create countless products we engage with daily. This includes everything from the keys on your keyboard, buttons on your toaster, or gears grinding away under your car’s hood. Plastic injection molded parts are everywhere. Today, we’ll take a closer look at injection molding, the process, […]

Should You Source Your Injection Molds from China or the USA?

Leave a CommentInjection molding dies, or injection molds, are the heart of molding process. It’s crucial for buyers to source them from reliable, trusted, quality-driven suppliers. They have a big decision to make: to build their molds in China, or closer to home in the USA. Often, this leads to questions about quality versus cost and delivery. […]

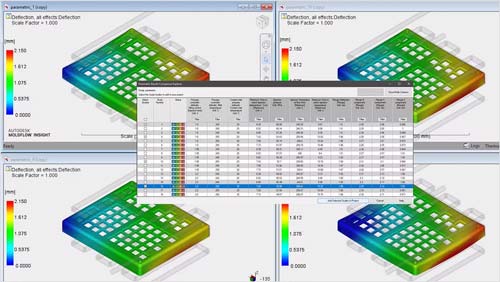

Five Reasons to Use Mold Flow Simulation Software for Injection Molding

Leave a CommentAre you leveraging mold flow simulation software to optimize your molds and injection molding process? You should be. Here’s why: injection molding is a complex process, and is subject to threats such as warping, uneven cooling, material defects, and much more. Historically, these challenges were only discovered through trial and error, leading to costly mold […]

The Importance of Surface Finish, Texture, and Draft Angles in Injection Molded Part Design

Leave a CommentThere are three aspects of plastic part design that are often overlooked, but crucial for manufacturing success: surface finish, texture, and draft angles. Understanding and optimizing each is critical for fabricating consistent, high quality plastic components efficiently. The first question that comes to mind: if these are so important, why are they often overlooked? We’re […]