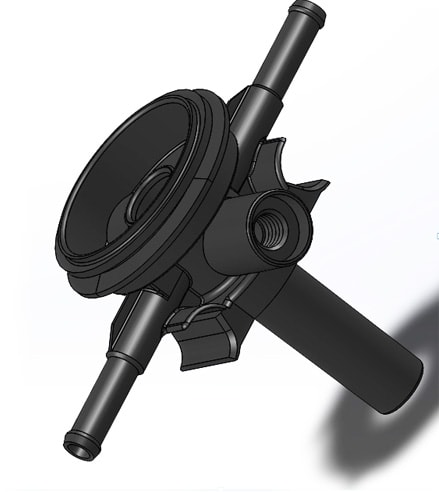

PDI Molding has the technical competencies to produce geometrically complex injection molded parts for a diverse range of industries. We manufactured the glass-filled nylon component highlighted here for an automotive industry application. This fitting module is a component of a filter housing assembly for a fuel system, and it demonstrates our expertise in mold design.

The tooling design was very robust. It integrates four slides to form the outside dimensions, and one of the slides incorporates an unscrewing action activated by a hydraulic cylinder. It also features a 3-plate system with multiple gates to permit the mold to fill easily. Although the part weighs only 45 grams, we molded it on our digitally controlled 200 ton Niigata to ensure zero variation in part weight and critical dimensions.

With overall dimensions of 3.5” in length x 4.0” in width x 2.5” in height, the module features an SPI B-3 and textured finish. We conducted dimensional inspections and fit tests to confirm we met the ±.002” tolerance specification. The client, impressed with our quality results, issued a blanket order for parts to be delivered on a weekly basis.

To learn more about this project or our injection molding capabilities, contact us today.

Notes:

PDI Molding provides custom plastic injection molding of many complex components for several industries. This glass filled nylon component is part of a filter housing assembly for an automotive fuel system. This part is molded in our all electric 200 ton Niigata machine. The mold for this part is very complicated. The outside of the part is formed by four slides. One of the slides houses and unscrewing action which is activated by a hydraulic cylinder. The part is gated using a 3-plate system with multiple gates. This part only weighs 45 grams but needs to run in a 200 ton press because of all the actions.