Category Archive: Plastic Injection Molding

With plastic injection molding, there are two types of mold configurations that may be used: standard self-contained molds and modular insert molds. Today, we’ll compare the key aspects of both types.

Self-Contained and Modular Insert Molds – Defined

Let’s start with a definition for each. Self-contained molds consist of all components integrated into a singular unit or a mold frame. These include the core, cavity, and other necessary components within a single base. Conversely, a modular insert mold is comprised of separate interchangeable components. The primary parts are the frame and the mold itself, which gets inserted into that frame.

Part Complexity

Self-contained molds are custom-made and, therefore can facilitate more complex part designs. When compared to modular insert molds, self-contained ones allow for intricate cavities, cores, and cooling channels.

There are some limits to what modular insert molds can handle. They can’t facilitate complex

operations involving for example gear assemblies. However, some insert molds can support

cam actions (side action).

Tooling Lead Times

Since self-contained molds are typically designed and fabricated from scratch, they take longer to produce. Conversely, insert mold frames are readily available, and while the insert itself does take some time to make, it’s much less than what’s required to build an entire self-contained mold from scratch.

Longevity

In the world of injection molding, longevity translates to cycles. In other words, how many impressions can be made in that mold before it needs to be replaced? Note that, regardless of configuration, longevity also depends on various factors including material and maintenance. Self-contained molds tend to outlive insert molds, as they are usually comprised of higher-quality materials.

In the world of injection molding, longevity translates to cycles. In other words, how many impressions can be made in that mold before it needs to be replaced? Note that, regardless of configuration, longevity also depends on various factors including material and maintenance. Self-contained molds tend to outlive insert molds, as they are usually comprised of higher-quality materials.

Cost

Conversations around cost are rarely simple these days, and this topic is no exception. Let’s start here: self-contained molds have higher tooling costs due to their custom nature. Modular insert molds are lower in cost since they have interchangeable inserts, thus reducing the need for mold frames. Remember, with insert molds, you are essentially paying for the “guts” of the mold, and not the entire assembly including the frame, helping to keep a lid on tooling costs.

If design changes are made, insert molds win again. However, keep in mind that self-contained molds generally last longer, and the lifetime cost may be lower than an insert mold. Similarly, if only specific hi-wear components of the tooling need to be replaced over time, insert molds offer more flexibility since the entire tool doesn’t need to be rebuilt.

Before we wrap up, we need to talk about part volume. Let’s put tooling costs aside for a

moment. If the injected component is a high-run part, in the hundreds of thousands, then the

price of the components themselves will be lower with a multi-cavity self-contained mold. This

allows for multiple pieces to be made at one time, which significantly reduces cycle time and its

associated costs.

Which is Best?

So, what will it be, self-contained mold or modular insert? It depends. For instance, we have a customer who supports the aviation market, but their parts are simple and are ordered in short runs. Perfect for modular insert molds. Conversely, we have an automotive customer with an uncomplicated part, but we use a self-contained mold. If you’ve read this far, you know why – it’s a high-volume run (500,000+) produced with a multi-cavity mold.

While some jobs may use either, in the end, the decision will rely on the requirements of the job, including volume, complexity, frequency of design changes, and related considerations.

Scientists estimate that there are 5 trillion tons of plastic in the world’s oceans. FIVE TRILLION!* It’s hard to wrap your head around that number, isn’t it? Couple that with the ever-increasing global demand for plastic, and the oil it is derived from, and you have a perfect storm. Thankfully, plastic is recyclable. Today we’ll look at some approaches to plastic recycling, and dive into the benefits of sustainable injection molding.

Scientists estimate that there are 5 trillion tons of plastic in the world’s oceans. FIVE TRILLION!* It’s hard to wrap your head around that number, isn’t it? Couple that with the ever-increasing global demand for plastic, and the oil it is derived from, and you have a perfect storm. Thankfully, plastic is recyclable. Today we’ll look at some approaches to plastic recycling, and dive into the benefits of sustainable injection molding.

First, let’s consider the use of plastics during the plastic injection molding process. For parts to be formed, molten material must travel through channels known as runners into the mold’s cavities. Once the parts have set, the plastic strip-like pieces formed within the runners, ironically also known as runners, have served their purpose. This excess plastic may be as much as 50% of the job’s material usage! That creates a tremendous amount of plastic that’s ripe for recycling.

How Do Injection Molders Recycle Plastic?

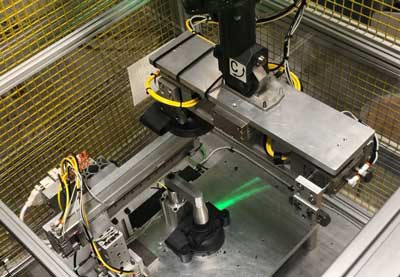

A robotic arm picks up the runners, and feeds them into the grinder for in-line recycling.

There are several ways a manufacturer can handle this excess material. In many cases, they will simply collect it, and send it out for recycling. A third party will take the plastic, which will eventually be recycled. To complete the cycle, the fabricator may buy recycled plastic to use as raw material for production. While this does help conserve resources, the processes to properly recycle plastic are complex, costly and demand more natural resources.

Alternatively, plastic shops may recycle in-house. There are two main methods of doing this:

- They collect the excess material during production, then send it to another part of the facility for regrind and reuse.

- In modern automated shops, like Plastic Design, the material is collected, reground and reused in-line, as part of an extremely efficient plastic injection process.

So, why go through all this effort to recycle plastic?

Resource Conservation

It’s pretty simple. Using recycled material helps conserve valuable natural resources such as oil. By keeping waste out of landfills, the manufacturer is contributing to a circular economy, giving materials a second life.

Waste Reduction

Keep in mind that about half of the material used in the plastic injection molding process doesn’t make it into the finished components. By capturing and recycling this plastic, significant amounts of waste are avoided, along with the costs it takes to handle, store and dispose of it. Putting less waste into the environment results in a much more sustainable manufacturing process.

Cost Reduction

While recycled plastic tends to cost more than virgin material, utilizing an optimal in-line recycling process actually drives material costs down. This is due to the many operational efficiencies it brings, across many departments. Think about it for a moment – it costs nothing to ship material that’s already in the building. There’s less handling required on the shop floor, thanks to automation. Since little disposal is required, associated fees are greatly reduced as well. The purchasing team also has less buying to do. There’s less raw material to stock, which means lower carrying costs.

Most industries can benefit from working with injection molders that are committed to a sensible recycling program. There are certainly some exceptions, such as the medical field or others that have strict requirements aimed at avoiding contamination. Otherwise, recycling plastics within the injection molding process brings many benefits to manufacturers, the environment, and, yes, the bottom line.

Can You Benefit from Using Recycled Plastics?

We’ve helped lots of brands reduce their carbon footprint and help keep plastic injection molding prices in check. Contact us now to see how we can assist you.

*SOURCE: National Geographic

There’s one question that comes up in practically every call we have with prospects and customers lately. You’ve probably guessed it already: “How can we reduce cost?”

There’s one question that comes up in practically every call we have with prospects and customers lately. You’ve probably guessed it already: “How can we reduce cost?”

It’s a fact. Every buyer wants to pay less for their injection molded parts, but without sacrificing quality. Thankfully, for many jobs, this is achievable if you know where to look. But you must be careful to preserve the part’s quality and integrity in the process, otherwise it could cost you in the long run. As the old saying goes, don’t be penny wise but pound-foolish.

There are several areas worth examining to help reduce injection molded part costs. These include part and tooling design, material, and manufacturing process considerations. Let’s take a look at these to see how successful cost reduction can be achieved:

Part and Tooling Design

The first place to start is with part design. Ultimately, your goal is to simplify the part wherever possible, Or, as we say here in the shop, KISS, or keep it super simple. Technically speaking, this translates to simplifying the geometry, minimizing undercuts, and eliminating unneeded features. When design is properly optimized, less material will be consumed and cycle time reduced. Less design complexity leads to lower tooling costs.

Additional cost saving opportunities may be found in the tool design and construction. Optimizing cooling channels, or conducting a mold flow analysis to identify areas for improvement. You should also consider options for using standardized mold components. By optimizing the gating system and cooling channels, you may be able to further cut cycle time and reduce material waste.

Are You Using the Best Material?

Material selection presents another potentially large opportunity for cost reduction. In our experience, the material is often over-spec’d. For instance, it is not unusual to see a job that calls for a resin that is say $10 or $20/lbs., when it could be made from a commodity material costing just a few dollars per pound. For medium and larger runs, this adds up to significant savings. Of course, you must be certain that the new material still meets the required specifications and operating conditions for the part. But there is no benefit in over specifying, it is sort of like installing stainless steel muffler on the Yugo.

Process Considerations

To keep production costs in check, it is critical to be sure that the process is optimized during process development stage. Reducing cycle time has a major impact on part cost. It is also a good idea to routinely revisit and verify that your process is at its optimum, study quality data, and eliminate any sources of waste or defects.

Automation and Robotics to the Rescue!

Another cost-saving process enhancement is to utilize automation and robotics when possible. As we explored in our previous blog, automation brings many cost-cutting benefits. It is especially useful when complex assemblies may be faithfully produced with the help of reliable automation. This reduces labor costs, material waste and cycle time.

Don’t Forgot About the Economies of Scale!

When practical, consider ordering in larger volumes. It is a simple principle. As run size increases, unit cost decreases. When coupled with reliable forecasting, this could lead to healthy savings. Don’t have a lot of space to store components that you don’t need yet? Many shops will offer stocking programs to help with warehousing. Though do keep in mind that carrying inventory is not free, so consider these costs when weighing against the benefits of longer production runs.

As you can see, there are plenty of ways to reduce injection molded part costs. It all comes down to reducing labor costs and cycle time while increasing process efficiency. As we mentioned earlier though, please be cautious. While saving money is certainly a good thing, you don’t want to sacrifice the part’s required properties in the process, especially for mission or safety-critical applications.

Want to see if we can help you reduce molded part costs?

Give us a call, tell us about your part, or send a drawing. We’ll be happy to review it and let you know what find!

As demand continues to grow for plastic injection molded parts and components, so does their complexity. To help keep up with this demand and competition, automation has become an integral player in the injection molding process. Automation is particularly beneficial for customers requiring plastic molded assemblies. Traditionally, assemblies have been put together by hand, requiring deep pools of skilled labor. While this approach may be sensible for smaller orders, automation for larger assembly runs is a must. Let’s take a look at the benefits that automation provides:

As demand continues to grow for plastic injection molded parts and components, so does their complexity. To help keep up with this demand and competition, automation has become an integral player in the injection molding process. Automation is particularly beneficial for customers requiring plastic molded assemblies. Traditionally, assemblies have been put together by hand, requiring deep pools of skilled labor. While this approach may be sensible for smaller orders, automation for larger assembly runs is a must. Let’s take a look at the benefits that automation provides:

Reduced Cost

Perhaps the most celebrated benefit is the smaller price tag that comes with automated assembly jobs. The primary reason: reduced labor costs. The math is fairly simple. Once configured, automated processes require minimal labor to stay up and running. Fully automated assembly can faithfully handle all the tasks including loading, cleaning, flashing, cutting, milling, and more. While the up-front costs may be considerable, their impact is reduced with larger or more complex runs that require costly skilled labor.

Improved Quality

Automation processes are tightly controlled, leaving little room for very little, if any deviation. This translates to improved quality, uniformity, and consistency across an entire run. This also leads to fewer rejects and less resulting waste, which further contributes to cost savings. As an added bonus, less waste makes the process more environmentally friendly too.

Decreased Lead Time

Strategically implemented automation brings efficiency to any manufacturing process that benefits from it. Why? It’s no secret, machines can often outperform humans for repeatable tasks. They can do them consistently and more efficiently. Machines can also run uninterrupted for extended periods of time, without breaks, even overnight. The result? Jobs are turned around much quicker.

Strategically implemented automation brings efficiency to any manufacturing process that benefits from it. Why? It’s no secret, machines can often outperform humans for repeatable tasks. They can do them consistently and more efficiently. Machines can also run uninterrupted for extended periods of time, without breaks, even overnight. The result? Jobs are turned around much quicker.

Enhanced Traceability

Traceability, or the ability to track the history of a manufactured component including its materials and process, has been a mandatory requirement for automotive and military applications for quite some time. It’s now moving to other industries as well, despite its complexity. Traceability requires a lot: excellent record-keeping, precise data collection, identification, documentation/reporting, and so much more. While automation can’t eliminate the paperwork, it can do something extremely helpful: serialize every part. Having the ability to uniquely identify a specific component, rather than just what lot it came from, is invaluable. Why? When coupled with other technology, such as machine vision inspection, the source of a defect can be quickly identified and remedied.

Not every injection molding assembly project can benefit from automation. Keep in mind, start-up costs are involved, and they can get pretty hefty. These include tooling, programming, machinery investments and other factors, So for lower runs of moderate complexity, generally around 10,000 pieces or so, people still will likely outperform the robots. That’s good. In the end, the goal is to be sure the customer has the best quality parts, on time, and at a reasonable cost.

To accomplish the highly technical process of injection molding plastic components, injection molding machines exert an extreme amount of pressure. The mold is subjected to two strong opposing forces, holding the mold open and forcing it closed. The pressure that pushes the mold together is called the clamping force, which is measured by tonnage. The strong opposing pressures are needed to keep the mold together during and after the molding material is inserted, while the opening pressure needs to be strong enough to hold the mold open while injecting the molding material. Each of these pressure types must be exerted to a specific factor, which needs to be carefully calculated before the injection process begins.

To accomplish the highly technical process of injection molding plastic components, injection molding machines exert an extreme amount of pressure. The mold is subjected to two strong opposing forces, holding the mold open and forcing it closed. The pressure that pushes the mold together is called the clamping force, which is measured by tonnage. The strong opposing pressures are needed to keep the mold together during and after the molding material is inserted, while the opening pressure needs to be strong enough to hold the mold open while injecting the molding material. Each of these pressure types must be exerted to a specific factor, which needs to be carefully calculated before the injection process begins.

What Is Tonnage?

The tonnage of an injection molding machine refers to the clamping force rate of the injection mold machine. For example, a 50-ton machine can produce a clamping force that is equivalent to 50 tons. Size is also important in injection-molded machines, as the larger the tonnage rate, the larger the machine. Tonnage is also determined in ton per square inch, and usually ranges from a 2 to 8-ton factor. It is extremely important to understand the required tonnage needed for a mold, which can be determined by a series of formulas.

Calculating Tonnage for Injection Molding

To calculate the correct tonnage for injection molding, there are three critical steps: surface area, melt flow, and part depth dimension. Finding the correct tonnage is critical in the molding manufacturing process, as using the wrong machine and clamp rate can damage the final part or product.

- Surface area: The first step to calculate the tonnage is to determine the surface area. This is done by measuring the length and width of the mold’s cavity, and multiplying the two together. If there are multiple cavities of the same size in the mold, multiply the number of cavities by the number of cavities. After the surface area is found, the tonnage factor is multiplied to the area. For precaution, a 10% safety factor should be included, to ensure that the pressure is not too strong.

- Melt flow: After finding the surface area, the next step is to calculate the melt flow, by using the Melt Flow Index (MFI). The MFI rates material’s viscosity rate, which has an inverse relationship with the MFI. The higher the viscosity, the lower the flow rate, and the lower the viscosity, the higher the flow rate.

- Part depth dimension: The final step to determine the correct tonnage is the depth of the part. If the dimension of a part is one inch, a factor of 10% clamping force must be added. An additional 10% is added for every inch about the initial one inch.

Dangers of Excess Tonnage

Using an injection molding machine that exceeds the pressure rate that is required can be dangerous to the product, machine, and mold. Excess tonnage can result in the problems of viscosity and flash. Injection molds need to have a very specific viscosity, as too thick or thin flow can result in an inoperable part. Flashing can also occur when the wrong tonnage pressure is applied, which results in an unwanted excess of material on the edges of the part. Using too little clamping force can also cause production problems, but an excess tonnage has the potential to be more destructive.

Contact Plastic Design International Inc. for Your Injection Molding Needs

At Plastic Design International Inc., we specialize in the production of a wide range of products, many of which are produced by our accurate and reliable injection molding machines. Our dedicated and knowledgeable staff has the expertise to produce our clients required part requirements, manufactured with the correct clamp force to ensure the highest quality possible. Request a quote to begin the process of receiving your expertly crafted injection mold product. Contact us with any further questions about the injection molding process, and how it can benefit your company today.

Plastic molding is a manufacturing process used to produce a wide range of parts and products from plastic materials. Two of the most common plastic molding methods are blow molding and plastic injection molding. While both processes rely on similar principles—e.g., heating the plastic material and applying pressure—their end products are completely different; blow molded components are hollow, while injection molded components are solid.

Plastic molding is a manufacturing process used to produce a wide range of parts and products from plastic materials. Two of the most common plastic molding methods are blow molding and plastic injection molding. While both processes rely on similar principles—e.g., heating the plastic material and applying pressure—their end products are completely different; blow molded components are hollow, while injection molded components are solid.

The following blog post provides greater detail regarding the differences between the two processes.

What Is Blow Molding?

The blow molding process is similar to glassblowing. A tube of plastic is heated and pumped with air until it turns into a hot plastic balloon (i.e., parison). The parison is then enclosed within a product mold. Air continues to flow into the parison until it expands and conforms to the shape of the mold, forming the desired part or product. Once the component has cooled, it is ejected from the mold.

This molding method has few engineering applications. It is generally used to create hollow and thin-walled components, such as bottles, cans, tanks, and other containers, suitable for use in normal operating and environmental conditions. The one-piece construction of these components eliminates the need for subsequent assembly processes, resulting in simple and fast production operations. These qualities, combined with relatively cheap machinery, result in low overall production costs.

During blow molding operations, it is important to keep in mind quality control measures. As many blow molded components feature thin walls, designers and engineers must identify the right wall thickness to ensure the component has the structural shape and integrity needed for the application. Some of the problems that may arise during operations include wall thinning, air leakage, streaks, and flash.

What is Injection Molding?

The injection molding process relies on precisely engineered molds and tooling. During operations, liquid plastic is injected into the mold (typically made from aluminum or stainless steel) at high pressures. Once the material is sufficiently cooled, it maintains the shape of the mold and, consequently, the desired part or product. At this point, it is ejected from the mold.

This molding method is used to create solid components. It is ideal for fulfilling high-volume orders of small and precise plastic pieces, such as handles, housings, and toys.

Compared to the blow molding process, the injection molding process accommodates more complex designs. Additionally, it can be used to create parts and products for demanding applications (e.g., high temperatures or stresses). For these situations, the components are generally made from engineering-grade plastics, such as ABS, glass-filled nylon, and HTPE.

Contact the Plastic Molding Experts at Plastic Design Today

Both blow molding and injection molding play a critical role in the manufacture of a wide range of plastic parts and products. If you’re looking for an injection molding partner for your next project, turn to the experts at Plastic Design today.

At Plastic Design International, Inc., we’ve provided custom plastic injection molding solutions for over 40 years. We utilize state-of-the-art technology, including automated conveyors, robotic sprue pickers, and CMM equipment, and maintain ISO certification to ensure the molded products we deliver fully meet our customers’ specifications and standards.

To learn more about our injection molding capabilities or discuss your project requirements with one of our representatives, contact us or request a quote today.

In the world of injection molding, longevity translates to cycles. In other words, how many impressions can be made in that mold before it needs to be replaced? Note that, regardless of configuration, longevity also depends on various factors including material and maintenance. Self-contained molds tend to outlive insert molds, as they are usually comprised of higher-quality materials.

In the world of injection molding, longevity translates to cycles. In other words, how many impressions can be made in that mold before it needs to be replaced? Note that, regardless of configuration, longevity also depends on various factors including material and maintenance. Self-contained molds tend to outlive insert molds, as they are usually comprised of higher-quality materials.

Scientists estimate that there are 5 trillion tons of plastic in the world’s oceans.

Scientists estimate that there are 5 trillion tons of plastic in the world’s oceans.

There’s one question that comes up in practically every call we have with prospects and customers lately. You’ve probably guessed it already: “How can we reduce cost?”

There’s one question that comes up in practically every call we have with prospects and customers lately. You’ve probably guessed it already: “How can we reduce cost?” As demand continues to grow for plastic injection molded parts and components, so does their complexity. To help keep up with this demand and competition, automation has become an integral player in the injection molding process. Automation is particularly beneficial for customers requiring plastic molded assemblies. Traditionally, assemblies have been put together by hand, requiring deep pools of skilled labor. While this approach may be sensible for smaller orders, automation for larger assembly runs is a must. Let’s take a look at the benefits that automation provides:

As demand continues to grow for plastic injection molded parts and components, so does their complexity. To help keep up with this demand and competition, automation has become an integral player in the injection molding process. Automation is particularly beneficial for customers requiring plastic molded assemblies. Traditionally, assemblies have been put together by hand, requiring deep pools of skilled labor. While this approach may be sensible for smaller orders, automation for larger assembly runs is a must. Let’s take a look at the benefits that automation provides: Strategically implemented automation brings efficiency to any manufacturing process that benefits from it. Why? It’s no secret, machines can often outperform humans for repeatable tasks. They can do them consistently and more efficiently. Machines can also run uninterrupted for extended periods of time, without breaks, even overnight. The result? Jobs are turned around much quicker.

Strategically implemented automation brings efficiency to any manufacturing process that benefits from it. Why? It’s no secret, machines can often outperform humans for repeatable tasks. They can do them consistently and more efficiently. Machines can also run uninterrupted for extended periods of time, without breaks, even overnight. The result? Jobs are turned around much quicker. To accomplish the highly technical process of injection molding plastic components, injection molding machines exert an extreme amount of pressure. The mold is subjected to two strong opposing forces, holding the mold open and forcing it closed. The pressure that pushes the mold together is called the clamping force, which is measured by tonnage. The strong opposing pressures are needed to keep the mold together during and after the molding material is inserted, while the opening pressure needs to be strong enough to hold the mold open while injecting the molding material. Each of these pressure types must be exerted to a specific factor, which needs to be carefully calculated before the injection process begins.

To accomplish the highly technical process of injection molding plastic components, injection molding machines exert an extreme amount of pressure. The mold is subjected to two strong opposing forces, holding the mold open and forcing it closed. The pressure that pushes the mold together is called the clamping force, which is measured by tonnage. The strong opposing pressures are needed to keep the mold together during and after the molding material is inserted, while the opening pressure needs to be strong enough to hold the mold open while injecting the molding material. Each of these pressure types must be exerted to a specific factor, which needs to be carefully calculated before the injection process begins.

Plastic molding is a manufacturing process used to produce a wide range of parts and products from plastic materials. Two of the most common plastic molding methods are blow molding and

Plastic molding is a manufacturing process used to produce a wide range of parts and products from plastic materials. Two of the most common plastic molding methods are blow molding and