At PDI Molding, we understand that precise plastic injection molded components and assemblies begin with superior mold making services and optimal tooling design. Our experienced in-house tooling department engineers and technicians leverage decades of combined custom mold design experience to ensure the most precise tooling results available. From design to delivery, we specialize in intricate plastic components and assemblies with complex geometries or other challenging features. If you have a problem that others aren’t willing to tackle, chances are, we’ve solved something similar over our many years in business. For plastic injection mold making and tooling, we will meet or exceed your quality demands.

Our Obsession with Technology

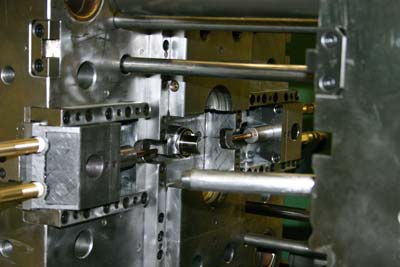

Advanced technology is at the core of everything we do at PDI Molding. Our fully equipped tool-room features CNC machines, EDM, etc., and CAD/CAM software, empowering us to create complex molds with efficiency and speed. By leveraging advanced software simulations and optimization tools, we minimize lead times, reduce costs, and optimize design for manufacturability. As a result, projects are delivered on time to the highest quality standards.

Innovative Plastic Injection Molding Fixturing Solutions

In addition to plastic injection mold making, we provide innovative fixturing solutions that help streamline production, improve and maintain part quality, and minimize downtime. Our team understands the importance of precision and repeatability, and we design our fixtures to meet the specific needs of your application. Capabilities include fixture design and manufacturing, including quick-change fixtures for increased efficiency. We also specialize in automated and robotic fixture solutions to supplement our automated injection molded assembly manufacturing services.

In addition to plastic injection mold making, we provide innovative fixturing solutions that help streamline production, improve and maintain part quality, and minimize downtime. Our team understands the importance of precision and repeatability, and we design our fixtures to meet the specific needs of your application. Capabilities include fixture design and manufacturing, including quick-change fixtures for increased efficiency. We also specialize in automated and robotic fixture solutions to supplement our automated injection molded assembly manufacturing services.

Plastic Injection Mold Making and Tooling for a Wide Variety of Industries and Applications

Whether your project requires single-cavity or multi-cavity molds, prototypes, or high-volume production tooling, our comprehensive capabilities cover a wide range of applications. We specialize in designing and manufacturing molds for diverse industries, including automotive, medical devices, consumer goods, and more. With our in-depth industry knowledge and expertise, we provide tailored solutions to meet your unique requirements. Our passionate commitment to continuous improvement guarantees that we stay ahead of industry trends, delivering optimal solutions for your plastic injection molding needs.

Capability Highlights:

- Prototype & Multi-Cavity High Production Tools

- Tooling Capabilities Both Domestic & Global

- Proficient and Highly Skilled Tool Design

- Hydraulic and Servo driven Core Pulls, Cam Activated or Unscrewing

- 3D Machining/CNC

- EDM

- Quick Turn-Around Mold Changes

- Mold Sampling and Evaluation

- Production Support/Maintenance

- Engineering Changes – Design & Implementation

- Innovative Fixturing

- SolidWorks

Need help solving a complex plastic molded part challenge? Contact us today for assistance or a quick quote.