The Importance of Injection Mold Maintenance, and How To Do It

Leave a CommentKeeping your plastic injection molds properly maintained is crucial to the long-term success of any molding program. When doing so, you will drive down costs, reduce downtime, and keep deliveries on schedule, all leading to better profitability. Today, we’ll take a deeper look at the benefits of proper mold maintenance, and dive into some tips on how to keep your injection molds properly maintained and functioning.

Benefits of Proper Mold Maintenance

Improved Quality – Proper mold maintenance will lead to higher quality products by preventing defects such as flash, sink marks, and warpage.

Improved Quality – Proper mold maintenance will lead to higher quality products by preventing defects such as flash, sink marks, and warpage.- Increased Lifespan – A well-maintained mold can last for many years, saving money on replacement costs.

- Reduced Downtime – Mold breakdowns can cause significant downtime, depending on the extent of the damage. Turn times could be substantially extended as a result, leading to weeks or even months in the event a new mold may be required. Preventing mold breakdowns with a solid maintenance program will help keep production running smoothly and on schedule.

- Improved Efficiency – A well-maintained mold will operate more efficiently, leading to faster cycle times and increased production output. As an added bonus, scrap rates will be reduced as well. This is good for your bottom line, and the environment.

Tips for Maintaining Your Plastic Injection Molds

Before we jump in, let’s keep in mind that in almost all contract molding arrangements, the molding facility is responsible for maintaining and storing the injection molds. Since you are ultimately at their mercy, it’s important to make sure they have proven (and well- documented) maintenance procedures in place.

Maintenance broadly fits into three categories as follows:

- Preventative Maintenance – is performed on a regular schedule to help prevent problems before they occur. This typically includes cleaning, lubrication, and inspection of the mold. More on that in a minute.

- Corrective Maintenance – is done to repair problems that have already occurred. This usually consists of repairing damaged parts, replacing worn components, and adjusting mold settings.

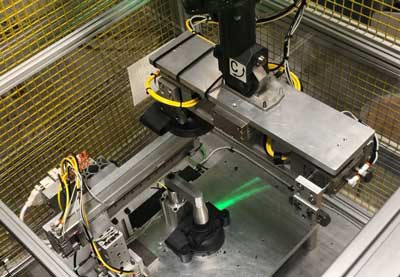

- Predictive Maintenance – uses technology to monitor mold performance and identify potential problems before they occur. This can help to prevent costly repairs, unplanned downtime, and extend the lifespan of the mold.

We recommend performing preventive maintenance on a monthly or quarterly basis, depending on the types of mold, material, and production schedule. This should include:

- Cleaning the mold regularly to remove debris and buildup.

- Lubricating the mold to help prevent wear and tear on the moving parts.

- Inspecting the mold for damage. The idea is to catch small problems before they turn into much bigger ones.

- Keeping a maintenance log that tracks the mold’s history and to help identify trends that may indicate potential problems.

At PDI, we inspect every mold for wear and damage after each run, regardless of run time. The maintenance plan is dictated by how many cycles it has endured. For instance, if the run was short, it will undergo a simple cleaning and greasing. Longer runs will undergo a complete cleaning, including disassembly and sonic cleaning. More complex molds that have endured higher runs will go through this as well, but may also have components such as gears changed.

Proper storage is as important as a good maintenance program. Molds should be stored in dry, climate-controlled environments. Remember, moisture and steel don’t mix!

Let’s face it: plastic injection molds are costly investments. So, just as you would do with you car, or any other big-ticket mechanical item, make sure injection molds are properly maintained and stored. Be sure to work with a shop that’s protecting your investment. Doing so will lead to improved efficiency, predictable delivery times, fewer headaches, and the best part: increased profits.

When it comes to creating prototype molds for injection molding, choosing the right material is crucial. Two common options for prototype mold construction are aluminum and soft steel (P20). Today, we’ll compare these two materials to help you make an informed decision. For the purposes of today’s discussion, we’ll be talking about “late stage” prototype molds. These are molds that are likely to be used for medium to high volume production runs, not just to knock out a few early-stage prototypes.

When it comes to creating prototype molds for injection molding, choosing the right material is crucial. Two common options for prototype mold construction are aluminum and soft steel (P20). Today, we’ll compare these two materials to help you make an informed decision. For the purposes of today’s discussion, we’ll be talking about “late stage” prototype molds. These are molds that are likely to be used for medium to high volume production runs, not just to knock out a few early-stage prototypes. Heat Conduction – aluminum dissipates heat quickly and efficiently, meaning reduced cooling time during the injection molding process. Steel holds heat longer, leading to extended cooling times, which could lengthen production time. Also consider the required melting point of the material being molded. For those that require higher values, steel is the way to go.

Heat Conduction – aluminum dissipates heat quickly and efficiently, meaning reduced cooling time during the injection molding process. Steel holds heat longer, leading to extended cooling times, which could lengthen production time. Also consider the required melting point of the material being molded. For those that require higher values, steel is the way to go.

In the world of injection molding, longevity translates to cycles. In other words, how many impressions can be made in that mold before it needs to be replaced? Note that, regardless of configuration, longevity also depends on various factors including material and maintenance. Self-contained molds tend to outlive insert molds, as they are usually comprised of higher-quality materials.

In the world of injection molding, longevity translates to cycles. In other words, how many impressions can be made in that mold before it needs to be replaced? Note that, regardless of configuration, longevity also depends on various factors including material and maintenance. Self-contained molds tend to outlive insert molds, as they are usually comprised of higher-quality materials. Scientists estimate that there are 5 trillion tons of plastic in the world’s oceans.

Scientists estimate that there are 5 trillion tons of plastic in the world’s oceans.

There’s one question that comes up in practically every call we have with prospects and customers lately. You’ve probably guessed it already: “How can we reduce cost?”

There’s one question that comes up in practically every call we have with prospects and customers lately. You’ve probably guessed it already: “How can we reduce cost?” As demand continues to grow for plastic injection molded parts and components, so does their complexity. To help keep up with this demand and competition, automation has become an integral player in the injection molding process. Automation is particularly beneficial for customers requiring plastic molded assemblies. Traditionally, assemblies have been put together by hand, requiring deep pools of skilled labor. While this approach may be sensible for smaller orders, automation for larger assembly runs is a must. Let’s take a look at the benefits that automation provides:

As demand continues to grow for plastic injection molded parts and components, so does their complexity. To help keep up with this demand and competition, automation has become an integral player in the injection molding process. Automation is particularly beneficial for customers requiring plastic molded assemblies. Traditionally, assemblies have been put together by hand, requiring deep pools of skilled labor. While this approach may be sensible for smaller orders, automation for larger assembly runs is a must. Let’s take a look at the benefits that automation provides: Strategically implemented automation brings efficiency to any manufacturing process that benefits from it. Why? It’s no secret, machines can often outperform humans for repeatable tasks. They can do them consistently and more efficiently. Machines can also run uninterrupted for extended periods of time, without breaks, even overnight. The result? Jobs are turned around much quicker.

Strategically implemented automation brings efficiency to any manufacturing process that benefits from it. Why? It’s no secret, machines can often outperform humans for repeatable tasks. They can do them consistently and more efficiently. Machines can also run uninterrupted for extended periods of time, without breaks, even overnight. The result? Jobs are turned around much quicker. To accomplish the highly technical process of injection molding plastic components, injection molding machines exert an extreme amount of pressure. The mold is subjected to two strong opposing forces, holding the mold open and forcing it closed. The pressure that pushes the mold together is called the clamping force, which is measured by tonnage. The strong opposing pressures are needed to keep the mold together during and after the molding material is inserted, while the opening pressure needs to be strong enough to hold the mold open while injecting the molding material. Each of these pressure types must be exerted to a specific factor, which needs to be carefully calculated before the injection process begins.

To accomplish the highly technical process of injection molding plastic components, injection molding machines exert an extreme amount of pressure. The mold is subjected to two strong opposing forces, holding the mold open and forcing it closed. The pressure that pushes the mold together is called the clamping force, which is measured by tonnage. The strong opposing pressures are needed to keep the mold together during and after the molding material is inserted, while the opening pressure needs to be strong enough to hold the mold open while injecting the molding material. Each of these pressure types must be exerted to a specific factor, which needs to be carefully calculated before the injection process begins.

Plastic molding is a manufacturing process used to produce a wide range of parts and products from plastic materials. Two of the most common plastic molding methods are blow molding and

Plastic molding is a manufacturing process used to produce a wide range of parts and products from plastic materials. Two of the most common plastic molding methods are blow molding and